MEA Activation Mechanism And Type

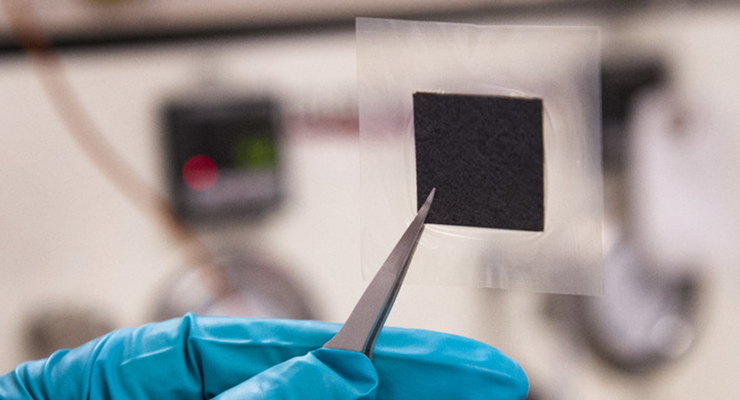

The core component of the proton exchange membrane fuel cell (PEMFC) is the membrane electrode.

MEA (Membrane Electrode Assembly), its performance greatly determines the performance of PEMFC. The performance of several main components of MEA (electrocatalyst, proton exchange membrane and diffusion layer) and the preparation process of MEA certainly have a great influence on its performance, but in order to enable PEMFC to quickly reach its optimal state and Work performance. Before the MEA is prepared and assembled into a fuel cell stack for normal test operation, the MEA is usually activated. In addition, for PEMFC performance degradation caused by long-term parking for a period of time, the performance of PEMFC can also be restored to a certain extent through MEA activation.

The activation of PEMFC can increase the activity of the platinum catalyst, increase the utilization rate of the catalyst, strengthen the hydration of the proton exchange membrane, and improve the output performance of the fuel cell. Therefore, the choice of MEA activation method is very important to the performance of PEMFC. A reasonable activation method can not only improve the performance of PEMFC, but also greatly reduce the activation time and reduce the amount of gas fuel, thereby greatly reducing the activation cost.

MEA activation mechanism

(1) Humidification process of PEM

The increase in the water content of PEM is conducive to the improvement of proton conductivity and the reduction of ohmic resistance, which improves the efficiency of PEMFC. PEM humidification methods mainly include

The humidified reaction gas carries water vapor through the GDL to the surface of the catalyst to humidify the PEM;

The water generated at the cathode through the electrode reaction humidifies the PEM through concentration diffusion.

(2) The establishment process of electronic transmission channel

In the MEA of PEMFC, Pt/C catalyst and GDL are good conductors of electrons. During the activation process of the electrode, especially after the forced activation of variable current, the comprehensive resistance R value of PEMFC becomes significantly smaller than the inactive R value. The inevitable result of the establishment of electronic channels in the activation process.

(3) The establishment process of proton transmission channel

Protons are exchanged and transferred through the hydrophilic cation exchange group of perfluorosulfonic acid ionic polymer (lonomer)-SOsH. As the activation process (ie electrode reaction) progresses, the proton conductor lonomer can be transferred between highly dispersed catalysts. Form a continuous three-dimensional network, so that protons can be better transmitted.

(4) Establishing process of gas transmission channel

In PEMEC’s MEA activation process, the humidified hydrogen and oxygen must first pass through the loose and porous gas diffusion layer, and then pass through the catalytic layer to the three-phase interface zone in contact with the membrane for electrode reaction. The activation process improves the structure of the gas diffusion layer, expands the gas channels and the three-phase interface in the catalytic layer, which is conducive to gas transfer.

(5) The establishment process of water transmission channel

The water content in PEMFC is determined by water transport and water balance. With the progress of the electrode reaction in the MEA activation process, along with the diffusion, transfer, generation and removal of water in the gas diffusion layer, electrode catalyst layer and membrane, the water gradually reaches equilibrium in the MEA and the transfer channel is established.

(6) Optimization process of electrode structure

The activation process causes a certain change in the microstructure of the MEA. This change tends to optimize the composition of the four channels (electrons, protons, reaction gases and water) in the electrode, that is, the ratio of various components.

In summary, the activation process of MEA is not only the humidification process of the proton exchange membrane, but also a complex process with multiple functions and influences. During the activation of the MEA, when the microscopic changes and structure of the MEA that are conducive to the increase in the utilization and activity of the electrocatalyst are established, the MEA will quickly show higher performance, thereby completing the activation of the PEMFC.

The activation of MEA is of great significance for improving the performance of PEMFC, reducing development costs and shortening product development time. therefore,

According to the actual application scenarios of PEMFC, fully combining the characteristics of three different activation methods and designing a reasonable activation process route can improve the performance and service life of PEMFC.

MEA activation type

There are many types of activation processes for PEMFC. According to the discharge state of PEMFC during actual application, it can be summarized into three types: pre-activated type (undischarged), discharge activated type and resume activated type (after a period of discharge).

- Pre-activation

Features of pre-activation: PEMFC is not discharged, which can reduce the time from the completion of assembly to the actual use of PEMFC, and the activation effect is average.

Examples of pre-activation: boiling MEA, PEMFC water injection or soaking and wetting.

The pre-activated type refers to pre-activating the MEA components or undischarged PEMFC before assembling the PEMFC stack, thereby reducing the discharge activation time of the PEMFC and improving its performance.

The pre-activation method can improve the Pt utilization rate of PEMFC and the wetting of MEA proton exchange membrane, thereby improving the performance of PEMFC. Although the pre-activation process is relatively simple and the performance improvement of PEFMC is limited, the pre-activation of PEMFC can save fuel consumption and shorten the subsequent discharge activation time, which greatly reduces the overall activation cost of PEMFC, which is very useful in the actual application process. It is necessary to pre-activate the PEMFC.

- Discharge activation

Discharge activation characteristics: The water produced during the discharge activation process gradually wets the MEA, increases the active sites of the catalyst and reduces the overall internal resistance of the stack, improves the overall performance and stability of the PEMFC, and has the best activation effect.

Examples of discharge activation: there are constant current discharge activation and variable current discharge activation.

Tianjin University uses three discharge activation processes for the MEA of PEMFC on the single cell. The research results show that forced activation by variable current is an ideal activation method, which can make the performance of MEA to a greater extent in a shorter time Play.

- Rejuvenation

Recovery activation characteristics: PEMFC is placed for a long time-a period of time, the use of recovery activation can restore the performance of PEMFC to a certain extent.

Example of reactivation: PEMFC parked for a long time.

After PEMFC is parked for a long period of time, its discharge performance will decay, mainly due to the evaporation of moisture inside the MEA and the oxidation of the catalyst surface, which cause the performance of PEMFC to decline. The discharge performance of PEMFC can be restored to a certain extent through the restoration activation method.

In order to prevent PEMFC from being parked for a long time and causing failure, a certain amount of N2 (humidity: 100% RH) can be sealed in PEMFC to avoid evaporation of water inside PEMFC and oxidation of Pt catalyst. This method has been verified in practice and is an effective PEMFC preservation method.

Summary

With the technological advancement of PEMFC, the preparation process of MEA has been continuously improved, and the current CCM type MEA has gradually transitioned to an orderly MEA. The research on catalysts has shifted from the current Pt and its alloys to non-precious metal and non-metal catalysts, and the proton exchange membrane has also developed from Nafion membrane to composite membrane and new proton exchange membrane. Therefore, it is necessary to conduct an in-depth study on the activation mechanism of PEMFC. According to the preparation process of MEA, design a reasonable activation process to improve the comprehensive performance of PEMFC more effectivel

Comments

Post a Comment